Tokenizing Physical Products: A first step to incentivizing the right behavior for Circularity

Identify a x10 better opportunity for a circularity solution

Originally written in the summer of 2020.

The path to creating a sustainable circularity solution is based on the premise that you will be able to create and sustain an x10 better solution than the status quo. The word “better” here is contextual and depends on the value proposition combination (e.g., smaller, greener, plastic-free, reusable). Your solution is likely going to fall into one of the following five business models:

- Circular Supply — Replacement of traditional production inputs with bio-based, renewable, or recovered material or goods.

- Resource Recovery — Collecting, sorting, and secondary production for use in new products.

- Product Life Extension — Design for durability, reuse, maintenance, and repair, remanufacturing. Keep products and materials in use.

- Sharing Economy — Peer to Peer (P2P) model of acquiring, providing or sharing goods often facilitated by an online portal.

- Product-as-a-Service — Intensional design of products to sell the service instead of the product itself (e.g., renting a washing machine)

A product or service journey starts with a business opportunity. The changing purchasing habits, ecological overuse of natural resources, and government regulations change the calculus of what it means for a product to be x10 better. A circular solution starts with a specific business or social problem that needs to be solved.

Circular economy products usually imply redesign. Therefore the design objectives for a product or a service must be measurable and fitting for your operating environment. The goal is to have a solution that’s ten times better than the status quo because an order of magnitude “better” is needed to change human behavior. A good example is Uber or Lyft. It’s x10 easier and more convenient to use a ride-hailing service than to call a taxi. At the design stage the creation, execution, and operational constraints must be specified to set the scope and boundaries of the product or service. Design constraints narrow the design choices and enable creativity.

Use the aircraft servicing metaphor as the mental model to prepare for scaling

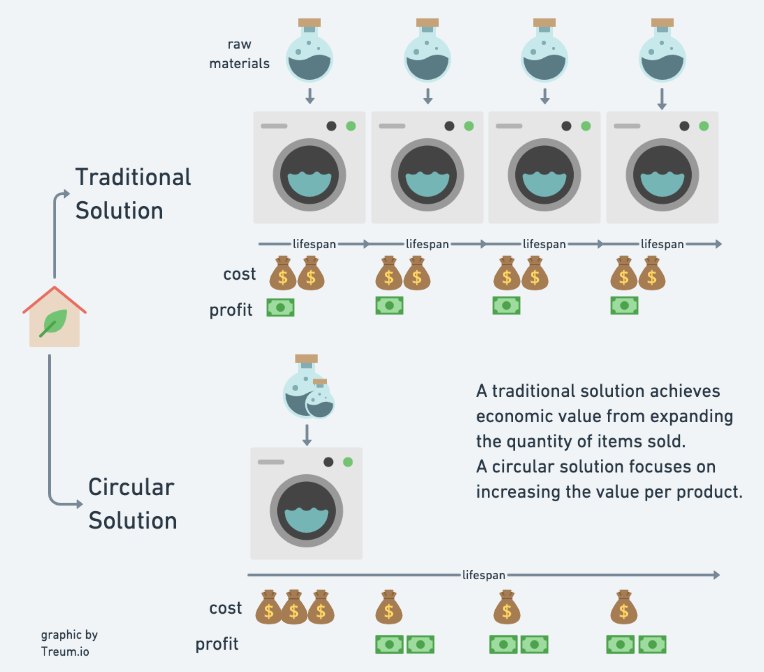

The scale of a circular product or a service can be achieved with efficient use of capital, resources, and operational processes. The economic value and benefit from a product or a service grows with scale. The key differentiator between the linear and circular economy is that the benefit (or value created) does not need to come from the quantity of a product or a service produced. It can come from efficient recirculation of the items or its components in the market where it can provide the highest degree of value.

Think of arrival to departure turnaround time for a commercial airliner as a mental model. The efficiency for re-circulating a durable item has been perfected in practice by the commercial air travel industry. An efficiently used plane is constantly in circulation serving different destinations in different climates multiple times a day. The engines of a plane in circulation never fully cool off except for the pre-scheduled maintenance windows or anomalies. A massive coordination between airlines, airports, and servicing personnel occurs to keep the service running on time, safely, and economically (the three design objectives for an airline).

It may feel that the aircraft management level of efficiency may only be achieved by well coordinated conglomerates such as WalMart, Ikea, Nestle, and Phillips with existing IT infrastructure and massive resources. The good news is that tamper proof public utility IT infrastructure necessary for a massive and global coordination already exists. More on that later. For now, you should assume that the pay as you go public network to support this kind of massive coordination is accessible to you and your stakeholders.

Select key measures to show traction and prepare for product instrumentation.

The linear economy and the “take-make-waste” product life cycle requires a one way set of measures. As we know from the circular economy paradigm a circular product is designed and programmed to come back into the ecosystem. Or designed to stay in service for a longer period of time while being supported by an ecosystem.

At such early stages it’s important to focus on metrics that will show circularity traction. For your role in the life cycle it may mean units in circulation, units idling, time for item’s return, lifetime value left in a unit. For other stakeholders it may be time to refurbish, time to re-sell, time in storage. For every role in the circular movement of your product the “what’s in it for me” question must be asked to identify qualitative and quantitative attributes. Examples of this can be revenue, reputation, volume, quality, etc. The lean and effective circular economy networks will operate with airliner-like efficiency, but without a centralized coordination authority. The products will be programmed to incentivize the “right next circular step”.

The lifecycle of a product and its re-circulation capabilities must be designed from the beginning. Associated measures must be set to monitor traction and the economic value produced per product. Every product will have different domain specific properties, but every circular product or a service will have very similar categories related to the five business models noted above. The key to success is proper instrumentation of re-circulation capabilities for each product.

The economic benefit to the manufacturer or the seller does not necessarily come from the quantity of the products solved, but from the economic value a product or a service generates over the lifetime of that product. Just enough tamper proof instrumentation, identity, and ownership information must be built into the products to account for improvisation in the circular ecosystem that is only being built. The circularity enablers, such as re-sellers, recyclers, auctioneers, will need to be incentivized to support the circular movement of a product. The state of the product must be monitored and its return cycle(s) must be measured and anticipated. It’s important to acknowledge that our society’s infrastructure is not set up for mass scale circular economy operations. Just to name a few: the reverse logistics processes are missing and product life extension service providers are too small.

Instrument your products for success

Once the full product lifecycle is approximated you can focus on instrumentation of items and components for successful circulation and value capture.

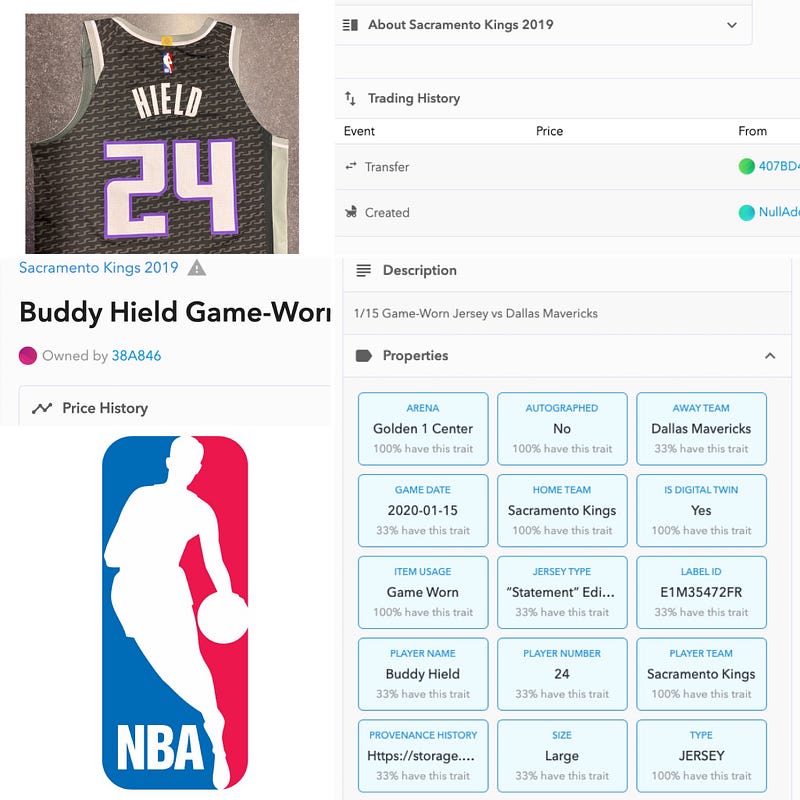

Digital Twin — a tamper proof digital fingerprint is required for every product. A digital fingerprint must be authentically set by the producer or by other authoritative trusted entities. In some cases a digital twin may have a physical appearance, such as NFC tag, but in all cases the fingerprint should be tethered to a trusted public blockchain in the form of a token. This digital fingerprint and a token are generated typically at creation time of a product or a service. Anchoring to a public blockchain, such as Ethereum, is critical for all future programmable actions and verifiable tamper proof history recording in the product passport.

Product Passport — a frictionless and tamper proof record, based on a public blockchain token, to make changes to the item’s state and grant access to data and money locked into a product. A token enables product programmability. This is the key to global and frictionless scalability for circular items. Programmability enables verifiable ownership or lease transfers and assures tamper proof history of the product. It enables guaranteed instant payments when contractual terms have been fulfilled, e.g., a battery has been properly serviced, or when desired actions are taken by a user, e.g., a cashable carbon credit offset issued when a maintenance is performed on time.

Prepare for real-world circular economy conditions

In the real-world circular economy a product passport must independently and verifiably speak on behalf of your product without a centralized database run by you. This means anyone should be able to retrieve the data on product components or material composition and be able to take the right next circular step. The current owner of the token representing a product is usually the stakeholder that needs to take the right next circularity step. When the step is taken, the ownership is transferred to the next logical owner in the circularity value chain, and the previous owner is rewarded. The rewards can be financial (e.g., stable coin) or anything that matters to that stakeholder in that context (e.g., a discount coupon, an accounting credit from a manufacturer, or a voucher for airline miles). Remember that blockchain tokens enable programmability. In certain cases the right next step may be delaying a consumer action. In other cases, incentivizing to quickly resell a product on a second hand marketplace and transfer token ownership to a new owner may be the right next step.

In a frictionless circular economy the right incentives are critical for the various actors to engage and advance the design objectives. Programmed incentive mechanisms built on a public blockchain will encourage the right next step to be taken and to improve the chances of your product making the full cycle, therefore meeting the initial design objectives.

Conclusion

Successful circular economy businesses must operate at an order of magnitude improvement over the status quo. These businesses will keep their products in circulation with efficiency of a commercial airline. This will be achieved by instrumenting a product with a digital fingerprint represented by a token on a trusted public blockchain such as Ethereum. Token enables programmability of an item to incorporate right incentives for the success of the circularity objectives. This means the ownership can be tracked, transferred, the history of the item maintained in a tamper proof way, and the item’s current owner actions rewarded through monetary or other compensation options. This directed, but not prescribed, approach positions items for recirculation in a circular economy by frictionlessly sharing the economic value derived from the item with all stakeholders who contribute to keeping the item in circulation.